CCQ Furnace Creation: Difference between revisions

No edit summary |

No edit summary |

||

| Line 6: | Line 6: | ||

== Instructions == | == Instructions == | ||

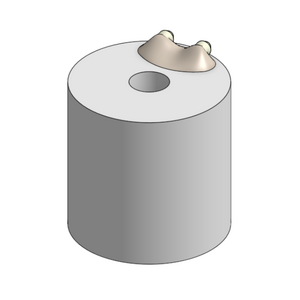

[[File:CCQ furnace sample (onshape)3.png|alt=CCQ furnace sample (onshape)3|thumb|CCQ furnace]] | [[File:CCQ furnace sample (onshape)3.png|alt=CCQ furnace sample (onshape)3|thumb|CCQ furnace]] | ||

* Please refer to the general directions for all furnaces located [[ | * Please refer to the general directions for all furnaces located [[CFF Preparation|here]]. Use these directions when instructed below. | ||

# Bending the Leads: | # Bending the Leads: | ||

| Line 20: | Line 20: | ||

#: Refer to step 6 through 10 in [[CFF Preparation|CFF preparation]] | #: Refer to step 6 through 10 in [[CFF Preparation|CFF preparation]] | ||

#: For CCQ: Use about 4 grams of potting cement. | #: For CCQ: Use about 4 grams of potting cement. | ||

# Ensuring Proper Alignment: | # Ensuring Proper [[Furnace Installation|Alignment]]: | ||

#: If the furnace does not allow the inlet port furnace aligner tool (TL-IP-FA) to freely pass in and out, use a 1/2" threaded rod. | #: If the furnace does not allow the inlet port furnace aligner tool (TL-IP-FA) to freely pass in and out, use a 1/2" threaded rod. | ||

#: Spin the bit and gently remove the material causing the obstruction. | #: Spin the bit and gently remove the material causing the obstruction. | ||

#: Ensure the furnace aligner can pass through the hole unassisted. | #: Ensure the furnace aligner can pass through the hole unassisted. | ||

Revision as of 16:50, 13 August 2024

Instructions

- Please refer to the general directions for all furnaces located here. Use these directions when instructed below.

- Bending the Leads:

- Make a sharp 90-degree bend in the leads 1/16 inch above the back surface, so the leads point away from the center of the furnace.

- Make a second bend so the leads run along the cylinder about 1/16 inch above the surface.

- Clipping and Insulating the Leads:

- Clip the leads to length using the furnace lead sizer (TL-FLS).

- Insulate the leads with fish-spine beads.

- Terminate each lead with a Molex male pin.

- For CCQ: Clip leads approximately 57 mm from the bend; use 12 beads per lead.

- Potting Cement Application:

- Refer to steps 2 and 3 in CFF preparation

- Refer to step 6 through 10 in CFF preparation

- For CCQ: Use about 4 grams of potting cement.

- Ensuring Proper Alignment:

- If the furnace does not allow the inlet port furnace aligner tool (TL-IP-FA) to freely pass in and out, use a 1/2" threaded rod.

- Spin the bit and gently remove the material causing the obstruction.

- Ensure the furnace aligner can pass through the hole unassisted.